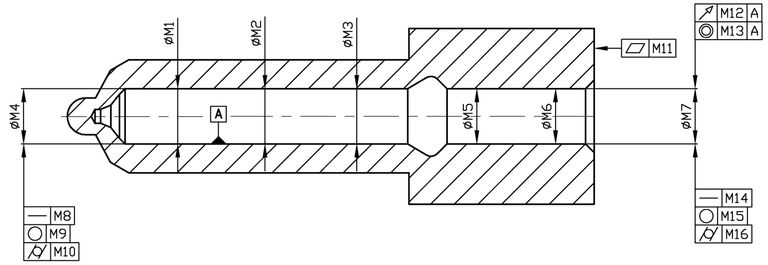

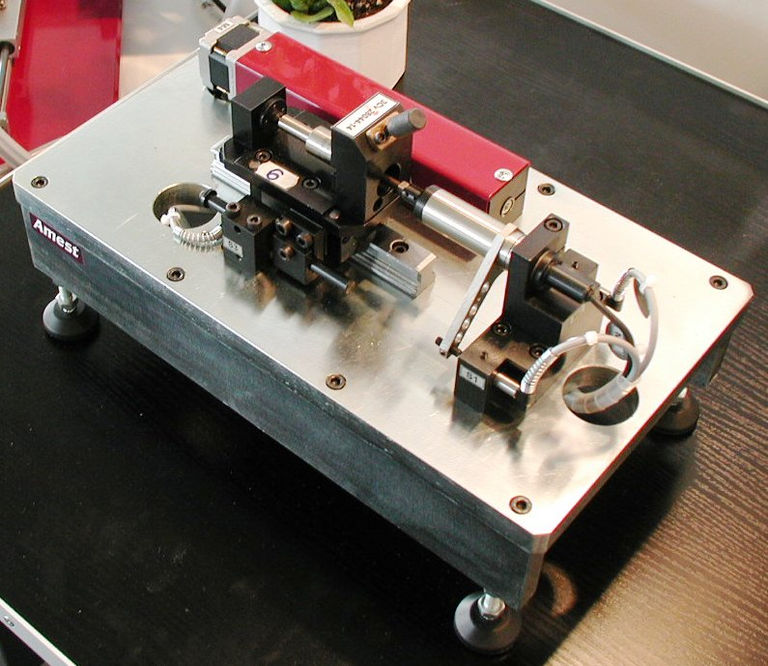

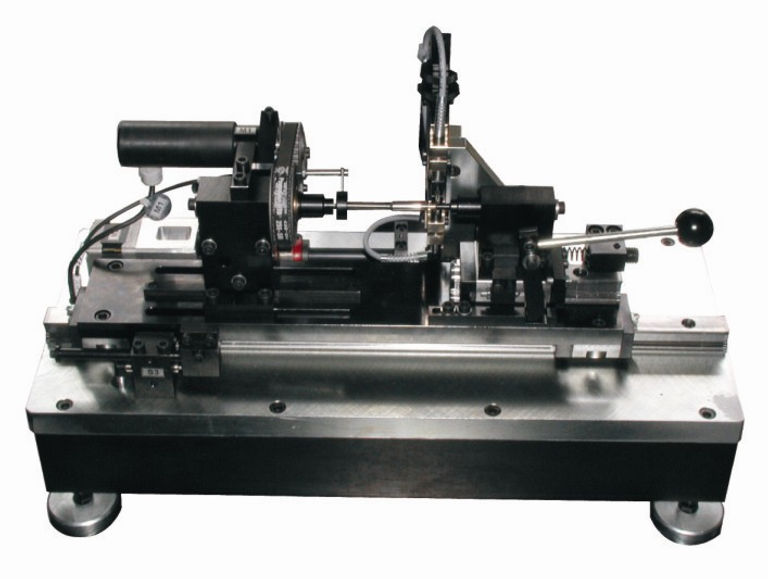

The measuring station designed for diameter, straightness and cylindricity jet bore measurement consists of a rigid foundation plate. On the plate, there is a linear guideway the carriage of which is operated by a program-controlled stepping motor. Using 4 screws, it is possible to fasten one of five clamps on the carriage, according to the type of the jet measured. The measurement itself is realized by means of a dynamic measurement pin (see attachment), which measures the internal diameter of the jet using adjustable number of cross-sections, and, furthermore, the circularity and straightness. As an integral part of the station there is worktable plate, switchboard and evaluation electronics.

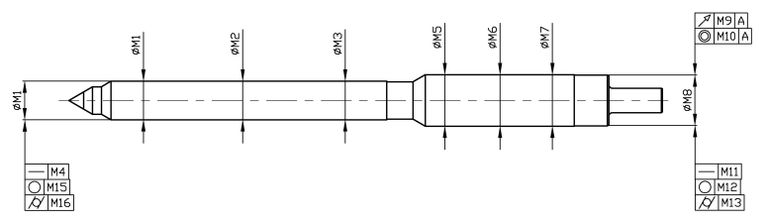

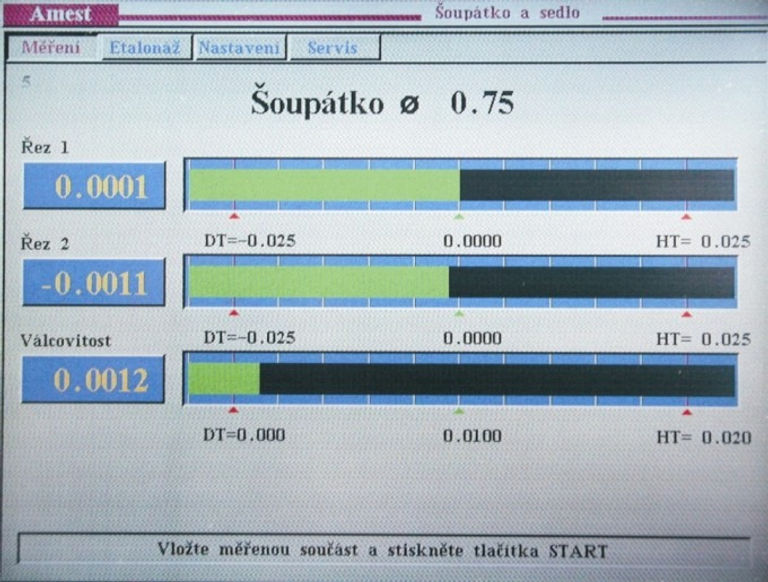

Example of measured parameters

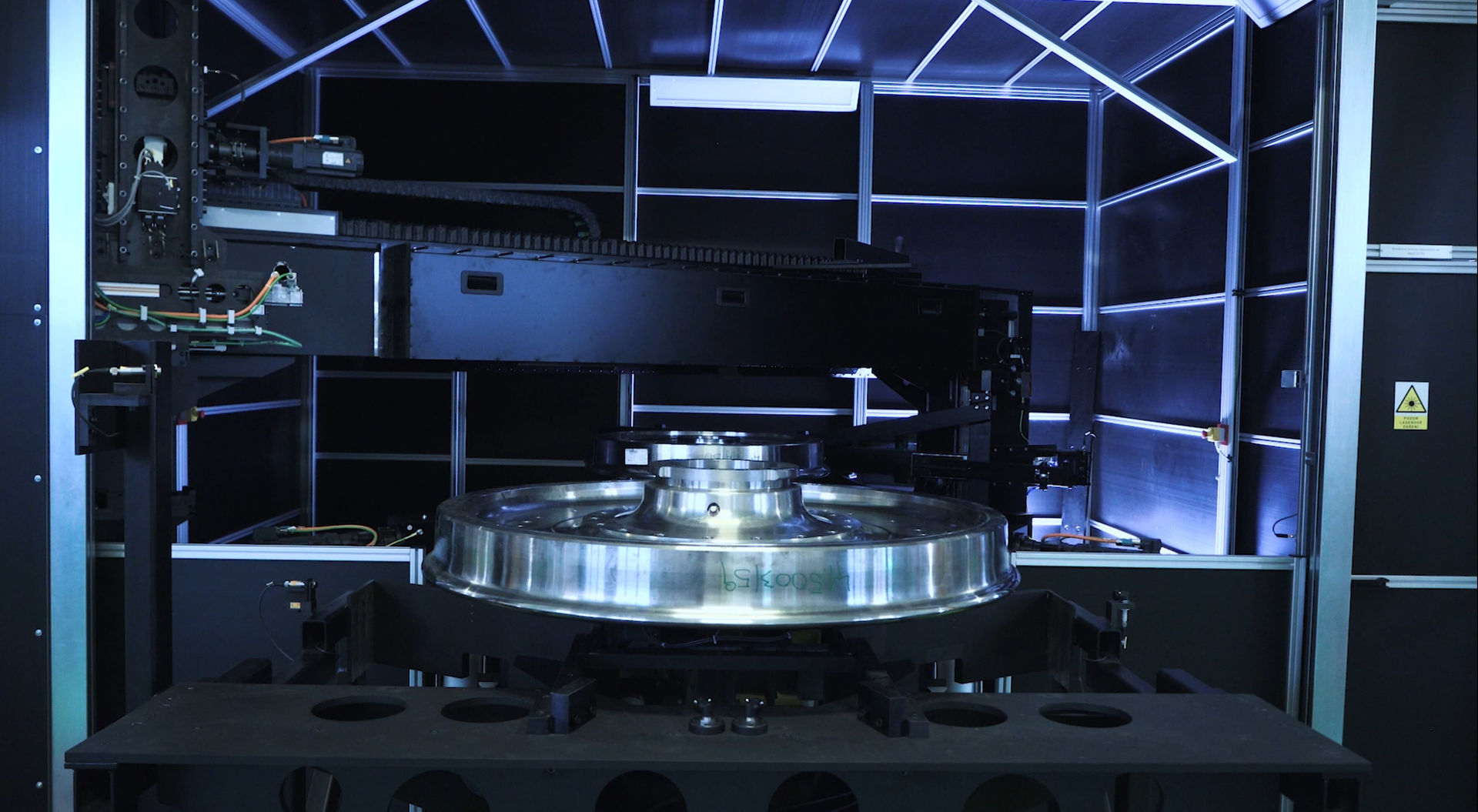

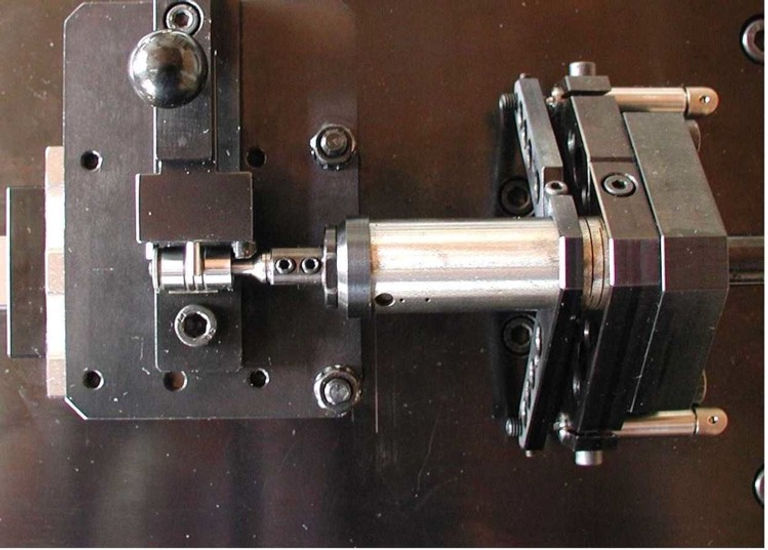

On the stand frame, there is a linear guideway on which the clamp table, along with the measuring component i.e. a needle moves. As an integral part of the table there is clamping mechanism and propulsion of the measured component. Furthermore, on the frame, there are 2 adjustable gauges fastened that scan the data intended for evaluation in the Amest electronic system. The table with the clamped component, which is being measured, moves by means of a screw that is operated by a controlled stepping motor.

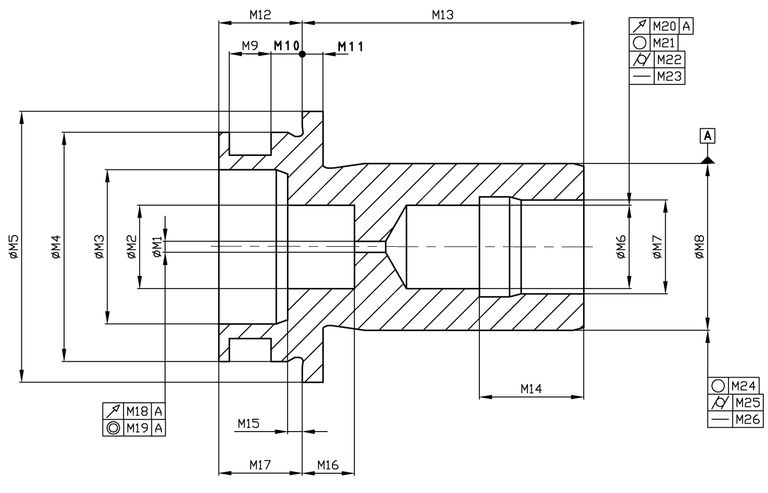

Example of measured parameters

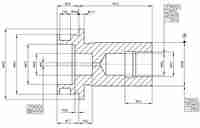

The station is designed for measurement of internal diameters after the honing process was completed. The measurement on a stand is carried out automatically after a component has been loaded. The station has an electronic measuring and evaluation system, a switchboard and an air treatment unit.

The measurement stand consists of a foundation plate, dynamic pin with 4 replaceable tips, 4 replaceable clamping sets for the respective standardized size with a hold intended for the linear guideway and a sliding system with 3 pneumatic cylinders with continuous adjustable backstops. The movement of the measuring components towards the measuring positions is pneumatic; the control consists of 2 push buttons positioned on the table.